Wall-climbing robot for rust removal put into use

Rust and adhesion of marine creatures are two constant headaches for ocean-going vessels. To ensure the working condition of a vessel, it’s necessary to clean up iron rust, deteriorated paint and adhesive marine creatures periodically. However, manual cleaning is typically labor-intensive and has some intractable problems, such as high risk of injuries caused by aloft work, environmental and physical hazards in sandblasting work and the escalating labor costs.

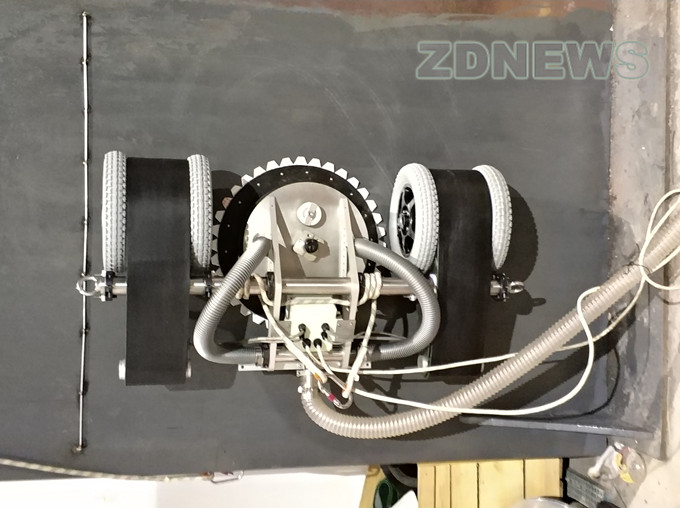

To tackle these problems, the team led by Prof. ZHU Shiqiang from the Ocean College develops a wall-climbing robot for rust removal, which has been put into use recently. This robot weighs 72 kilograms and has a carrying capacity of over 100 kilograms. It removes rust and paint using an ultra-high water jet of 200 MPa and vacuums wastewater into a collecting device from the deck simultaneously, thereby avoiding pollution caused by wastewater containing rust and paint. “The maximum efficiency and the mean efficiency of this robot are 81 square meters per hour and 40 square meters per hour respectively,” said Prof. SONG Wei, chief member of the team.

“There is an apparent contradiction between mass and magnetism, and we need a light magnet with remarkable magnetism,” SONG said, “Fortunately we solve this problem by optimizing the design of the magnetic circuit and the size of varying components. Moreover, we also manage to reduce the weight of the whole robot with the superb design of its mechanic structure, thus making it easy for workers to move it.”

The adhesion principle for a wall-climbing robot appears simple, but it turns out to be far more complicated in actual practice. Its performance is affected by the vessel type, the welding and painting techniques as well as the erosion of seawater. The team once encountered a Vietnamese bulk vessel with a very high welding seam. The robot got stuck very easily. “These bulges and curvatures influenced the sealing effect of vacuum, therefore undermining the efficiency of waste collection,” explained SONG.

This robot can also be applied to the maintenance of petrochemical storage tanks. At present, Zhoushan City, one of the major shipyards and oil storage centers in China, owns roughly 30 million cubic meters of petrochemical tanks. Once the raw oil storage base is completed, the capacity of petrochemical tanks will add up to 100 million cubic meters. The team looks forward to bringing this robot into full play in Zhoushan.

A sample robot with a greater carrying capacity and higher working efficiency is currently being assembled, and an amphibious robot will have been developed by the end of this year. More artificial intelligence technologies are expected to be incorporated into future wall-climbing robots.