Competition Highlight: Visually-guided Gluing Chaser in “Siemens Cup”

“Siemens Cup” China Intelligent Manufacturing Challenge is one of the important competitions that Zhejiang University Smart Factory Innovation Association participates in every year. In the 2020 “Siemens Cup” China Intelligent Manufacturing Challenge, the Visually-guided Gluing Chaser, designed by three members from the association—REN Yixin, HU Jiayi and CHEN Lu—clinched first prize thanks to their perspicacious marketing analysis and innovative design.

This system is designed for respirator masks with immense attention paid to tackling the most difficult and time-consuming gluing process during the outbreak of COVID-19. At present, virtually every mask gluing process is still operated manually in a non-standard manner and only a few factories adopt semi-automatic production lines. Against this backdrop, the team designs the Visually-guided Gluing Chaser to improve the efficiency of the gluing process and reduce human-to-human contact in industrial production in an effort to prevent and control the spread of the novel coronavirus.

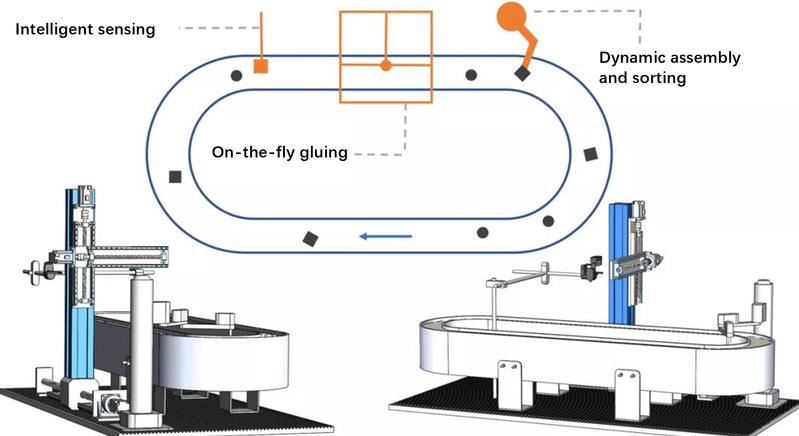

The Gluing Chaser consists of three parts: intelligent sensing, on-the-fly gluing, and dynamic assembly and sorting. It can apply glue to the external periphery of an object in any shape on the assembly line and use such algorithms as machine vision and trajectory planning to ensure an efficient and accurate gluing process. Furthermore, the gluing action can automatically align itself with the speed of the conveyor belt. After a specified drying time, the robot arm will carry out immediate assembly and sorting. This production line eliminates the need to stop the conveyor and saves 4 to 5 seconds in every step.

Meanwhile, the Gluing Chaser can realize the blended production of different mask models, thereby precluding the need for pre-sorting and shortening the process. When changes are made to the product plan or the production environment, it can be quickly adjusted to meet the needs of producing customized respirator masks. In order to achieve market-oriented intelligent manufacturing, the team also develops a big data system for production planning, which can predict the trend of the epidemic in each region and estimate the demand for different types of respiratory masks through modeling, enabling early production and instant response.

With the rising demand for robotic equipment in the manufacturing industry and the mounting concern of enterprises about environmental protection and the improvement of the working environment for workers, more intelligent, automatic and flexible gluing technology is in great need in the gluing process. The three students from Zhejiang University Smart Factory Innovation Association detect flaws with the production line and design their own product through their research, which enables them to get to the core of intelligent manufacturing and intelligent factory.