International team unravels the mystery of strength and ductility in high-entropy alloys

Researchers from Zhejiang University, the Georgia Institute of Technology, and the University of California, Berkeley, engage in collaborative research to find out the truth about high-entropy alloys (HEAs). Their findings on outstanding toughness and plasticity of HEAs are published in the October 10 issue of the journal of Nature.

HEAs, a class of materials that contain five or more elements in near-equiatomic proportions, display exceptional mechanical performance, including superb strength, remarkable ductility and toughness, especially at low temperatures, making them potentially attractive materials for many structural applications. All five elements in the most studied HEA alloy, CrMnFeCoNi, belong to the first row of transition metals in the Periodic Table, with a similar atomic size and electronegativity. How would the random alloying effect and associated solid-solution strengthening theories be affected if an element from another row were substituted?

“As a crystallographic defect or irregularity within a crystal structure, dislocations will exert an immediate impact on its strength and ductility. From the perspective of dislocation theories, dislocation structures and behavior are directly affected by atomic-scale elements, particularly the alignment and distribution of various atoms,”says YU Qian,professor in the School of Material Science and engineering.

![HAADF image of atomic structure, taken with the [110] zone axis, and corresponding EDS maps for individual elements of Cr, Fe, Co, Ni and Pd.](/_upload/article/images/2d/88/8abcc042431ea7b1e5e345264663/aa01e1dd-96cc-4e20-8125-1ff138ea454d.png)

Researchers employ atomic-resolution chemical mapping to reveal the element distribution of the widely studied face-centered cubic CrMnFeCoNi Cantor alloy and of a new face-centred cubic alloy, CrFeCoNiPd. In the Cantor alloy, the distribution of the five constituent elements is relatively random and uniform. By contrast, in the CrFeCoNiPd alloy, in which the palladium atoms have a markedly different atomic size and electronegativity from the other elements, the homogeneity decreases considerably; all five elements tend to show greater aggregation, with a wavelength of incipient concentration waves as small as 1 to 3 nanometres.

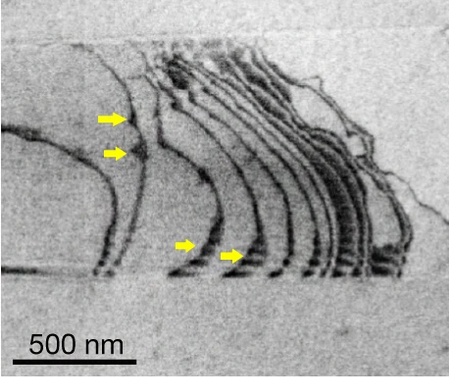

The resulting nanoscale alternating tensile and compressive strain fields lead to considerable resistance to dislocation glide. In situ transmission electron microscopy during straining experiments reveals massive dislocation crossslip from the early stage of plastic deformation, contributing to strong dislocation interactions between multiple slip systems. These deformation mechanisms in the CrFeCoNiPd alloy, which differ markedly from those in the Cantor alloy and other face-centered cubic high-entropy alloys, are promoted by pronounced fluctuations in composition and an increase in stacking-fault energy, leading to higher yield strength without compromising strain hardening and tensile ductility.

The atomic-scale mapping of chemical distribution and associated correlation analysis (including autocorrelation and cross-correlation) open up opportunities for resolving the nanoscale chemical structures in both HEAs and other solid solutions. This study may provide a fundamental basis for tuning compositions and atomic configurations to produce new deformation mechanisms and mechanical properties in HEAs. It is expected that HEAs will enjoy extensive applications in aviation and polar materials as well as in the anti-impact domain.