Hybrid macrofiber with spider silk-like supertoughness

Researchers applied a biomineralization‐inspired technique to synthesize functional organic–inorganic fibers that are structurally complex and, furthermore, industrially manufacture spider silk fibers (SSF)‐like artificial fibers with a supertoughness. Their findings are published in Advanced Functional Materials.

Nature provides an infinite amount of inspiration for human beings and biomimicry is one of the most extensively used methods among scientists. Natural SSF are characterized by their superhigh tensile strength (1150 ± 200 MPa) and remarkable fracture toughness (165 ± 30 J g−1) as well as their salient breaking strain (>50%). These features are attributable to the well-organized supramolecular networks in SSF: proteins self-assemble to form rigid nano-confined crystalline β-sheets and a flexible amorphous matrix. However, SSF cannot be obtained in large quantities from spiders owing to the fact that spiders cannot be farmed due to their cannibalistic behavior. Collecting SSF from webs is also extremely time-consuming and is therefore not profitable. Another typical biomaterial that combines a rigid crystalline phase and a flexible amorphous phase is biological bone. During biomineralization, the inorganic building blocks, hydroxyapatite (HAP), orderly assemble into collagen bundles to generate hard tissues. In contrast with the tensile strength of SSF, biological bone is marked by its toughness.

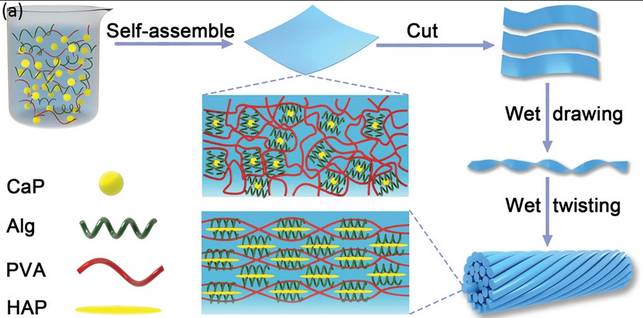

Against this backdrop, Prof. TANG Ruikang and Dr. LIU Zhaoming from the Zhejiang University Department of Chemistry fabricated biomimetic mineralized organic-inorganic hybrid macrofiber by using HAP and organic polyvinyl alcohol (PVA) to simulate the rigid crystalline and flexible amorphous protein blocks of SSF, respectively. This fiber is featured by a hierarchical ordered structure, a superhigh tensile strength of 949 ± 38 MPa, a specific toughness of 296 ± 12 J g−1, and a stretch ability of 80.6%. It consists of microfibers, and its outstanding performance (e.g., extreme tolerance to temperatures ranging from −196 to 80 °C and superior ability to inhibit the transverse growth of cracks) is attributed to the hierarchical arrangement as well as the organic-inorganic integrated structure within the oriented mineralized polymer chains.

Schematic illustration of the preparation process and network microstructure of the PVA/Alg/HAP hybrid macrofiber

The biomineralization-inspired technique is of great significance due to its simplicity and efficiency, achieved by utilizing the sophisticated biomimetic mineralization tactic. The resulting fibrous material has promise for applications such as flexible ballistic fabrics owing to its excellent mechanical properties. More importantly, the composite materials PVA, Alg and HAP are inexpensive and highly available in markets. In addition, this fabrication process is simple, scalable, and cost-effective, and thus represents an alternative pathway for the development of the fiber industry.