Record achieved in methane oxidation to methanol using a molecular fence concept

Methanol is an important platform molecule for producing olefins, aromatics and other building blocks for fine chemicals. The energy-intensive conventional route to its industrial synthesis entails reforming of methane to syngas, followed by further conversion to methanol at high pressure. The direct partial oxidation of methane into methanol would be more appealing but is extremely challenging because of methane’s high C–H bond strength, negligible electron affinity, and low polarizability.

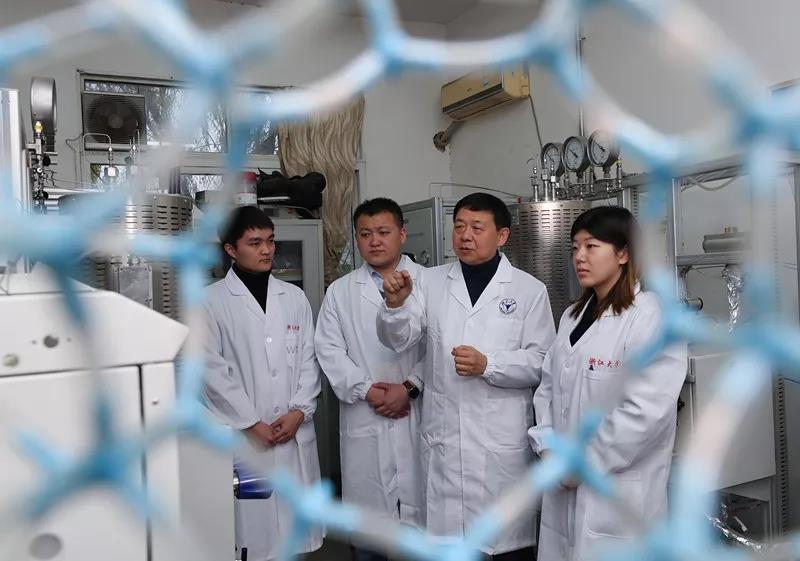

Over the past three years, Prof. Xiao Fengshou and Dr. WANG Liang worked together and developed a heterogeneous catalyst system for enhanced methanol productivity in methane oxidation by in situ generated hydrogen peroxide at mild temperature (70°C) with 17.3% conversion of methane, and record-high 92% methanol selectivity. This study was published online in the journal of Science on January 10.

In the study, XIAO Fengshou et al. finely controlled H2O2 diffusion in the partial oxidation of methane, using the concept of a molecular fence. AuPd alloy nanoparticles were embedded in aluminosilicate zeolite crystals, followed by hydrophobization that rendered the external surface of the zeolite hydrophobic by appending organosilanes.

Once the hydrophilic H2O2 forms from H2 and O2, the hydrophobic sheath hinders its diffusion from the encapsulated AuPd nanoparticles, enhancing its concentration in the zeolite crystals. At the same time, the hydrophobic methane molecules can efficiently pass through the hydrophobic sheath to access the AuPd nanoparticles. “The way the molecular fence locks hydrogen peroxide is much the same as the way a face mask prevents water loss,” observed WANG Liang.

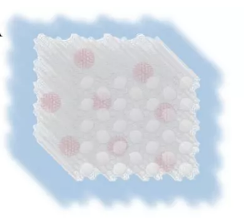

Blue:hydrophobic sheath; Grey: zeolites; Red: medal nanoparticles

What is intriguing about this heterogeneous catalyst system? “The whole system resembles an egg in structure: the alloy nanoparticle is the yolk, the zeolite is the albumen and the molecular fence is the eggshell,” remarked XIAO Fengshou.

The catalyst was synthesized by fixation of AuPd alloy nanoparticles within aluminosilicate zeolite crystals, followed by modification of the external surface of the zeolite with organosilanes. The silanes appear to allow diffusion of hydrogen, oxygen, and methane to the catalyst active sites, while confining the generated peroxide there to enhance its reaction probability.

The encapsulation of active AuPd nanoparticles inside zeolites and further modification of the resulting zeolite crystals by a hydrophobic sheath resulted in a zeolite nanoreactor with high local concentration of H2O2, which considerably enhances efficient oxidation of methane. Zeolites with hydrophobic surfaces could act as a powerful support for metal nanoparticles, and the molecular-fence concept should open a productive route to more-efficient catalysts for partial methane oxidation.

This work represents a large step toward the application of direct activation of methane to produce valuable products. “There is still a long way to go before its large-scale application, but with the increasingly ascending added value of transforming methane into methanol, there will be a lot of possibilities,” said XIAO Fengshou.