Reversible fusion and fission of GO-based fibers

If you feel that two gold rings are old-fashioned, you can ask a goldsmith to re-make a pair of rings by melting the old ones under high temperature. However, you are bothered by a twinge of regret after the rings are melted into liquid. Is it possible to get back the two original gold rings?

The answer is self-evident. Even if the remade gold rings look exactly identical to the former ones in appearance, corresponding internal components have been disrupted and re-distributed randomly.

For ordinary materials, once two objects are fused, it will hardly be reversible. Even when separated, they won’t be the same any more. Nonetheless, with four years’ efforts, the research team led by Prof. GAO Chao at the Zhejiang University Department of Polymer Science and Engineering discovered that graphene oxide (GO) sheets are able to deform adaptively. Corresponding macroscopic GO fibers have the capability of precisely reversible fusion and fission. A number of GO fibers can not only fuse into a thicker one but also separate into original individual fibers, as if they came with a “return key”. This study is of considerable importance to the reversible assemblies in the future. The research findings were published in the journal Science on May 7.

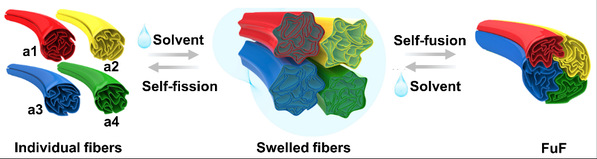

Schematic of precisely reversible fusion and fission of GO fibers

“Precise reversibility means that the number, size, component, structure, and performance of an object can be restored to its original state after a single fusion-fission cycle. In previous studies, researchers have not achieved the precise reversibility because some irreversible physical or chemical changes occurred at the material interface,” said GAO.

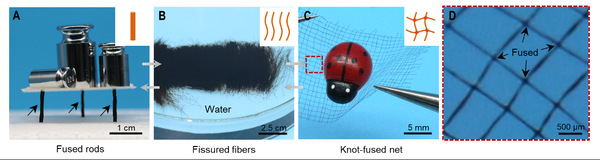

The research team found that the centimeter-scale assembly built by GO fibers could reversibly transform between different forms through fusion and fission. In their work, as many as 13,500 fibers were fused into one thick rod. This rod finally transformed into a flexible knot-fused GO net by fission and re-fusion. When related experimental process was reversed, the net would change back into a GO rod.

Reversible fusion-fission promises controllable transformation

between different GO fiber-based assemblies

After the whole process, individual GO fibers constituting the rod and net didn’t change. “By virtue of a certain treatment, the solid material fused by GO fibers can alter architectures and then restore to its original form. We have realized the precisely reversible assembly of macroscopic GO solids.”

The team led by GAO Chao has been committed to working on the macroscopic assembly of graphene for more than a decade. As early as 2016, they found that GO staple fibers can be interfused into non-woven fabrics through filtration.

In the following research, GAO Chao et al. found that GO is characterized by 2D topology, abundant chemical moieties, super-flexibility, and self-adhesion capabilities. Multiple GO fibers could fuse into a thicker one that features high density, low porosity, and moderate interfacial bonding. “They are easily fused together due to their remarkable affinity, but can still be separated since the bonding force is not as strong as steel,” said GAO.

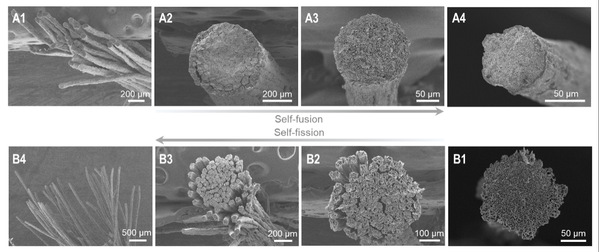

Sequential scanning electron microscopy images of fusion and fission involving 100 GO fibers

In this study, as many as 13,500 fibers with micrometer-scale diameter and centimeter-scale length were fused into one 1.2-mm-thick rod that was rigid and strong enough to support 680 times its weight. When the rod was put into a solvent such as water, it would gradually fissure into 13,500 original fibers. “During the whole process, individual GO fibers swelled about forty times in volume, thus ensuring sufficient and adaptive deformation of the surface,” said CHANG Dan, lead author of this study.

In addition, researchers found that fibers made from polymers, metal, or ceramic can be endowed with these abilities when coated with a micron-sized layer of GO. The concept was further extended to conventional fibers through GO coatings while providing the potential for recyclability.

“In contrast with previous studies, this fusion or fission process we completed is precisely reversible, controllable and large in material size, thus guaranteeing the effective recyclability of materials,” GAO said.

More information: CHANG Dan, a doctoral candidate at Zhejiang University Department of Polymer Science and Engineering is the lead author. Prof. GAO Chao, Dr. LI Zheng from Zhejiang University, and Prof. LIU Yi lun from Xi’an Jiaotong University are corresponding authors.