Turn brittle mineral into plastic substitute

Plastics bring much convenience to human life by virtue of their flexibility, plasticity, lightness and cheapness, but they also pose a considerable threat to the natural environment owing to their non-degradable bonds that lead to “white pollution”. In recent years, an increasing number of researchers have started to seek new “plastics” as an alternative to traditional petroleum-based plastics.

The research findings by Prof. LIU Zhaoming and Prof. TANG Ruikang from the Department of Chemistry, Zhejiang University, appeared in an article entitled “A flexible and degradable hybrid mineral as a plastic substitute” in the journal Advanced Materials. This mineral, which contains over 80% calcium phosphate (CaP) and less than 20% polymers, exhibits flexibility and mechanical properties similar to those of polymer plastics. It is marked by better hardness and thermostability. Moreover, it can be procured from nature and recycled after use.

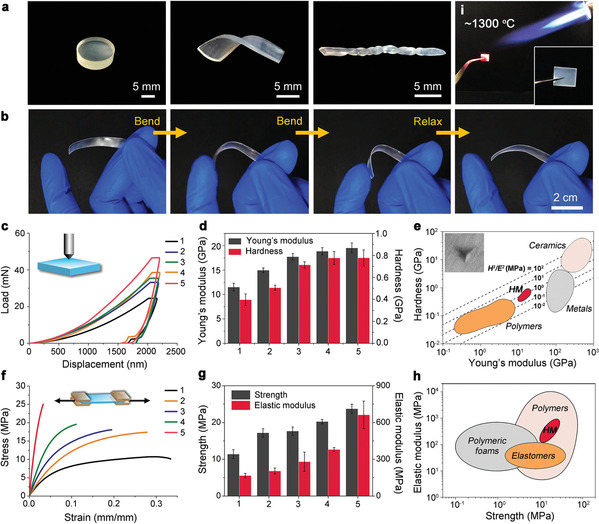

Comparison between natural minerals and hybrid minerals

Minerals are part of the natural environment and participate in geological cycles. The researchers noted that if they can be converted into plastic-like materials, such problems as pollution and recycling may well be evaded directly. Furthermore, ores are inexpensive. This technology is therefore suitable for extensive use.

Nevertheless, minerals are hard, brittle, and difficult to be shaped. It is therefore essential to overcome their intrinsic brittleness.

Shells, bones and teeth inspired the research team a lot.

“These natural biomineralized materials are composed of inorganic minerals, organic macromolecules and polymers. It is this small quantity of macromolecules and polymers that control the size and morphology of inorganic minerals,” said Prof. Liu. “This inspired us to explore similar means to achieve the regulation of inorganic ionic polymerization.”

Prof. Liu et al. selected polyvinyl alcohol (PVA) and sodium alginate (SA) as ideal biomimetic polymers and added them to CaP ionic oligomers so as to produce a hybrid material. These two polymers are reported to resemble collagen in bones in terms of chemical functional groups.

“More than 80% of the hybrid mineral is inorganic CaP, and the remaining components include PVA and SA,” said Prof. Liu. “These inorganic nanofibers are bonded by organic materials on a mesoscopic scale to form bulk materials on a macroscopic scale.”

By using transmission electron microscopy, the researchers noted that CaP nanofibers possessed periodic structural defects, exhibiting a lower ionic cross-linking degree than hydroxyapatite (HAP, a crystalline phase of CaP). As a result, the stable and tough inorganic ionic network could be assembled into a structure with three or four parallel ionic chains, thereby rendering the inorganic structure flexible.

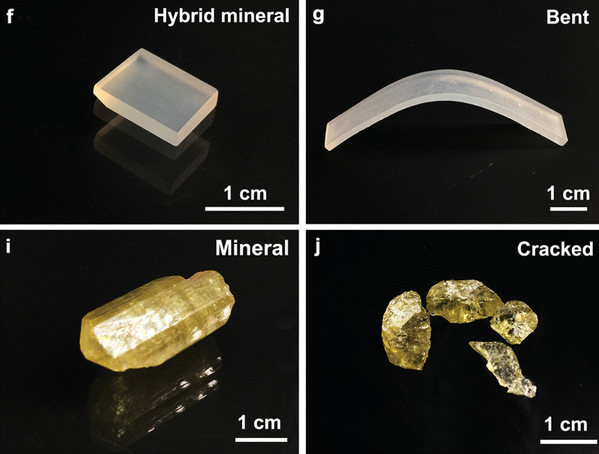

Mechanical properties and fire-retardant ability of hybrid minerals

Experiments showed that the tensile strength of this hybrid mineral amounted to about 20 MPa and its elastic modulus reached about 600 MPa. Like traditional plastic materials, it could be stretched and bended. Moreover, due to its high inorganic content, it exhibited greater hardness at roughly 0.8 GPa, thus less prone to scratching.

The researchers found that unlike common plastics which will be ignited and melted in flames, this hybrid mineral remained largely unchanged while burning and turned into a crystalline mineral similar to tricalcium phosphate after burning, thus losing its toughness.

Due to “white pollution”, it is not unheard-of that plastics are dumped into crystal-clear waters, microplastics are found in human bodies, and animals die from accidentally eating plastics. LIU et al. thus conducted experiments simulating weathering, precipitation and ingestion by animals.

They arrived at a conclusion that if this hybrid mineral were soaked in water for more than 3 months, its components—PVC and SA—would be dissolved and they would not cause any pollution because they are environmentally friendly. Moreover, the precipitated crystalline HAP was no different from mineral HAP in the geology.

Besides, the inorganic mineral material would be dissolved in an acidic environment with a pH of 4. Therefore, even if it were accidentally digested by an animal, it would be gradually degraded and ingested hypothetically. This would not cause any plastic blockage in animals’ digestive system.

Prof. Liu and his team will conduct follow-up research concerning how to reduce the cost in manufacturing.

“It is a significant breakthrough to produce a hybrid mineral whose inorganic content reaches 80%, but the remaining 20% of polymers makes it hard to turn into a real mineral,” said Prof. Liu. “We hope that we can discover the mechanism for the formation of CaP with periodic structural defects and completely remove its organic polymers, thus elevating the understanding, synthesis and structural control of inorganic materials to a higher level.”