Dialogue@ZJU: With WANG Guanyun, College of Computer Science and Technology

[Editor’s Note: Inspired by the seeds of the flowering plant Erodium, scientists from Zhejiang University, Carnegie Mellon University, the University of Pennsylvania, and Syracuse University designed a robotic seed carrier that can drill into the soil on its own, which is suitable for aerial seeding in harsh environments. Their study opens up a new avenue for agricultural seeding, vegetation planting, environmental monitoring, and ecological restoration. Their research findings were published as a cover article in the journal Nature on February 16. WANG Guanyun, an assistant professor from the College of Computer Science and Technology at Zhejiang University, is one of the corresponding authors. Below are the excerpts from the interview with WANG Guanyun.]

Q1: How did you become interested in the Erodium seed?

WANG: I first learned about the Erodium seed about ten years ago. During my studies in the United States, the project leader YAO Lining, a former Ph.D. student at MIT Media Lab who is now a professor at Carnegie Mellon University, introduced us to Erodium, a unique plant that mostly grows in arid deserts. This plant can spin itself by absorbing moisture from the air and thus drill its seed into the soil autonomously. In this way, the seed can stand a better chance of survival in complex wilderness environments. We found this type of seed fascinating and wondered how we could employ biomimicry to facilitate agricultural development.

Erodium seed

Q2: In what way did the Erodium seed inspire you?

WANG: Intelligent design is crucial in today’s society, and people want smart products that can autonomously sense users, perceive the environment, and respond accordingly. Such designs often require complex sensing and electronic controlling technologies, which I do not believe to be truly intelligent. Inspired by the Erodium seed, we explored the possibility of developing an “unplugged” smart product that takes advantage of the properties of materials and structures to achieve the desired functionality.

Fabrication and deployment

Q3: What research has been conducted on how to get seeds to drill into the soil in the scientific community?

WANG: There has been extensive research on morphing in the scientific field, most of which, however, focused on specific materials or mechanical problems. Our team has long been committed to studying shape morphing, with a greater emphasis on the feasibility of its application. For example, our team has developed a series of morphing mechanisms for 4D printing and applied them in the fields of transformable furniture, food, and clothing. It was from our previous research on 4D printing spiral deformation that the wood deformation mechanism springs.

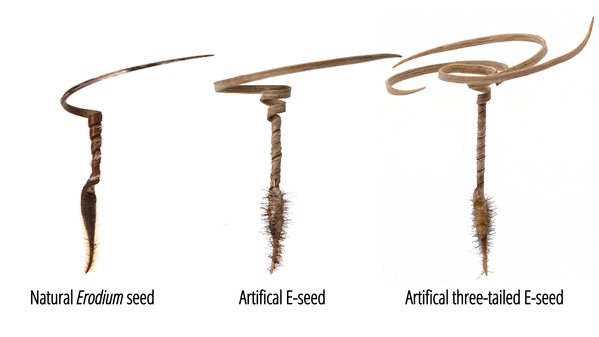

E-seed vs natural Erodium seed

Q4: How did your design background help achieve this bionic goal?

WANG: Design is a highly cross-disciplinary subject. Our team comprises scientists from different backgrounds, including design, materials science, mechanics, and marketing experts from the industry, and we have engaged in cross-disciplinary research for a long time. Thanks to our collective work, we formulated the final project.

Q5: What is the “intelligent side” of the bionic Erodium seed?

WANG: The E-seed we develop can change its shape in response to humidity and bury its head into the soil. For example, when it rains, the E-seed will rotate and expand its body after absorbing water, while after the rain, it will rotate reversely and contract its body. The whole process is like the forward and backward rotation of a drill. Through continuous spinning, the head of the seed slowly drills into the soil.

Germination test

Q6: What is special about your project?

WANG: Our E-seed project has more advantages over real Erodium seeds. The Erodium seed has only one tail, which often makes it unsuccessful in forming an angle between the seed head and the ground, leading to a low success rate in its drilling into the soil. In contrast, our E-seed can be customized, for instance, by adding three tails to the seed, thus ensuring that the head maintains a fixed angle to the ground after aerial seeding and greatly increasing the success rate of soil drilling. In addition, we can change the body size and customize the double helix structure of the E-seed to meet different needs in various scenarios.

E-seed Three tails

Q7: Is the process complicated in mass production?

WANG: Our materials and processing techniques are common, such as white oak, which is widely used in furniture manufacturing, common wood cutting and sanding equipment, and chemical washing materials and equipment. The whole processing method can be widely popularized. However, since our research is still in the experimentation stage, we are not sure what new challenge may arise in mass production.

The ZJU team is conducting an experiment for aerial seeding.

Q8: What future does the E-seed hold?

WANG: The E-seed can tremendously simplify the seeding process, for example, by being precisely distributed by drones in the future. The E-seed can also carry different types of seeds, such as vegetable seeds, grass seeds, and tree seeds, as well as microorganisms, fungi, fertilizers, etc. It can be widely used in agricultural seeding, vegetation planting, and ecological restoration in farmlands, post-disaster areas, and mining areas, thus facilitating the development of modern agriculture.

Image credit: The research team

Video credit: Morphing Matter Lab, Human-Computer Interaction Institute, Carnegie Mellon University; Zhejiang University; Syracuse University; University of Pennsylvania; Accenture Labs