Scientists develop ultra-resilient “frozen smoke” aerogel for extreme environments

Aerogels, often dubbed “frozen smoke,” are among the lightest materials on Earth. It's hard to imagine that such an ethereal substance could one day safeguard spacecraft or explore the Sun’s blazing vicinity. Yet, after more than a decade of deducated research, Professor GAO Chao's team from the Department of Polymer Science and Engineering at Zhejiang University has developed a highly elastic aerogel with a unique micro-dome structure that can withstand temperatures exceeding 2000°C (2273K), while remaining lightweight, resilient, and stable under extreme compression.

Dome-celled aerogels

This breakthrough stems from a novel yet simple fabrication method known as graphene oxide-based two-dimensional (2D) channel-confined foaming. Using this technique, the team has created hundreds of aerogel variants that combine outstanding thermal insulation with remarkable elasticity. The results open new possibilities for applications in deep-space probes, hypersonic aircraft, and nuclear fusion devices. Their findings were published in Science on July 17, 2025, in a paper titled “Dome-celled aerogels with ultra-high-temperature superelasticity over 2273 K”.

In lab tests, sheets of the new aerogel were compressed between two stainless steel “iron palms” to a paper-thin thickness — undergoing up to 99% deformation. Yet even after tens of thousands of compressions, the aerogel bounced back every time. Conventional aerogels would crumble under such strain, but GAO’s team managed to transform brittleness into bounce by re-engineering the material’s internal pore structure.

Demonstration of superelasticity at room temperature

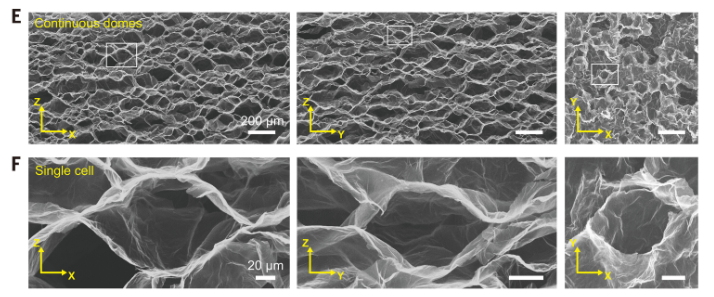

More than 90% of an aerogel is composed of micro- and nano-scale pores, typically honeycomb or arched in shape. GAO’s team replaced them with dome-shaped structures. “Conventional aerogels tend to have sharp-edged pores, while ours feature micron-scale domed surfaces,” explained Dr. PANG Kai, co-lead author of the study. Dome structures, commonly seen in nature and architecture, are noted for their exceptional load-bearing capacity and mechanical stability. “Egg cartons, for example, use domed hollows to absorb external impact more effectively,” PANG added.

In collaboration with Professor LIU Yilun’s team at Xi’an Jiaotong University, the researchers demonstrated that the non-developable geometry of these domes forms numerous reversible folds, allowing the material to store greater elastic strain energy. Computer simulations revealed that these micro-domes can store at least 10 times more strain energy than conventional pore structures, enabling superior elastic and compressive performance. GAO believes that this marks a new curvature design paradigm in porous materials, one that could fuel a wide range of new materials.

The team’s inspiration for the fabrication process came from the viral “elephant toothpaste” experiment. In that demo, hydrogen peroxide (H₂O₂) rapidly decomposes under a catalyst, producing a foamy explosion of gas. “We applied a similar principle by confining the gas-forming reaction within layers of graphene oxide,” GAO explained.

Graphene oxide, rich in oxygen-containing functional groups, captures metal ions efficiently and prevents them from leaching out. When a foaming agent is added under ambient conditions, spherical bubbles nucleate and expand between the graphene oxide layers, leaving behind the micro-dome pores. “It’s just like baking bread — those bubbles in the crumb come from carbon dioxide released by yeast,” said PANG. Unlike conventional techniques, this energy-efficient process doesn’t require freeze-drying, supercritical drying, or complex equipment.

Preparation of aerogels from the 2D channel precursor

SEM analysis of dome-celled aerogel

GAO’s team has long been a pioneer in aerogel development. In 2013, they fabricated a graphene carbon aerogel that, at the time, was the world’s lightest known material. Over the years, they have focused on refining fabrication methods to bring aerogels from lab scenarios to real-world applications.

According to Dr. XU Zhen, co-corresponding author of the study, the 2D confined foaming method is highly adaptable. Graphene can be combined with metals, oxides, or carbides to form hybrid aerogels, spanning 121 oxides, 38 carbides, and 35 metal systems, thereby greatly expanding the aerogel family. The team has also achieved controllable design of high-entropy compositions, incorporating up to 30 elements. “We hope this can become an innovation platform for a new class of materials, ranging from single-element to high-entropy composites, from conductive metals to insulating ceramics, from transparent to colored materials,” GAO said.

At 6.1 million kilometers from the Sun, NASA’s Parker Solar Probe holds the record for the closest human-made object to the Sun. Its limiting factor? Heat. Existing heat shields max out at around 1650°C. But could a material exceed that threshold?

Enter the “Graphene-Ceramic” aerogel. This 2D atomic-scale hybrid — half ceramic, half graphene — offers the strength of ceramics. Instead, it’s soft and “Q-elastic.” Lab tests showed that it retains 99% elastic strain across an astonishing temperature range: from a cryogenic 4.2K (−268.8°C) to a searing 2273K (2000°C). According to Dr. LIU Yingjun, co-corresponding author of the study, graphene in the hybrid suppresses ceramic recrystallization at high temperatures, while the ceramic layers stabilize the graphene and prevent slippage.

Aerogel stability under cryogenic & ultra-high temperature tests

To test the mechanical properties of aerogels at high temperatures, the team

built a high-temperature furnace for real-time observation.

Even more remarkably, the team’s high-entropy aerogels offer exceptional thermal insulation. At room temperature, they exhibit a thermal conductivity of just 13.4 mW/m·K, half that of air. Even at extreme conditions—1273K and 2273K—they maintain stable conductivities of 53.4 and 171.1 mW/m·K respectively, and remain intact after 100 cycles of thermal shock at 2273K. These features make them strong candidates for thermal protection in extreme environments.

“We believe that this 2D confined foaming method opens the door to an unexplored world of porous materials, rich with untapped performance and application potential,” said GAO. In the not-too-distant future, this smoky yet resilient material may help probes get even closer to the Sun—or even pave the way for thermal suits that allow humans to explore the deepest parts of Earth.

Adapted and translated from the article by Academic Committee of ZJU, Qiushi Fengcai

Translator: FANG Fumin

Photos by Academic Committee of ZJU, Qiushi Fengcai

Editor: HE Jiawen, ZHU Ziyu